NEWS

Welcome Back!

When an employee voluntarily leaves Dodson Boatyard, we use our old adage “Oh, you’ll be back.”

Amy Cochran started work at Dodson in 1980 as a dock girl at age 16. She became a launch driver at age 17 and she worked in the yard hauling and launching with a Travelift boat hoist or the 16 ton fork truck. She was with us until she graduated from Connecticut College. She then drifted off to work at other area boatyards. She ran her own varnish company for 15 years.

On November 1, 2018 Amy came back to Dodson to head up our seven person year round full time varnish department. Amy is highly skilled and very knowledgeable concerning all aspects of boats. In addition to managing our Varnish Department, Amy is a boat handler on land or water, head of quality control, but most importantly an outstanding person and we welcome her back to our team.

Welcome Back Amy!

Twenty years... and more!

It is with abundant pride and equal amounts of humility that we take this opportunity to recognize two outstanding members of the Dodson Boatyard team. It has often been said that a company’s most valuable assets are its employees. The two men we recognize here are indeed exceptional examples of this truth.

DAVE BOISVERT - 20 YEARS

Dave joined DBY in 1998. From the beginning he set an example for work ethic, competence, reliability, and positivity. His primary responsibility is as the Yard’s lead equipment operator. More specifically that means operating the Travelifts and hydraulic trailers that move and locate the vessels that DBY handles. Think about it. Such work entails an awesome burden reflected by the condition, quality and value of these boats. It is not easy but over his 20 years with DBY Dave has performed this work with exceptional, professional skill. Of course, other tasks have been requested of Dave over time, including rigging and carpentry assignments among others, and true to his character he never responded by saying, “that’s not in my job description” but rather worked willingly outside of such boundaries. Dave lives in Foster, RI on his family farm and makes the 45+ minute drive to Stonington in all weather. His passion is his 18’ Marshall Catboat MELINA, which he sails out of Wickford, RI, but only when he isn’t working on her. It may be the most perfect Marshall in existence.

STEVE KINGSLAND - 40 YEARS

No one is more refective of the institution that Dodson Boatyard has become than Steve Kingsland. 40 years! Unbelievable! And those 40 years have not been spent in an office but rather much of it on the water overseeing the harbor of Stonington. While Steve’s skill set is varied and diverse, including marine carpentry and rigging, above all else Steve has managed and maintained the “harbor hardware” (i.e., the moorings) for most of his tenure. Currently that involves some 112 DBY moorings in addition to approximately 85 private moorings. He is meticulous in his record keeping noting the specifics of the various mooring components, their condition, dates of installation and/or inspections. His knowledge of the harbor is unparalleled and invaluable. Steve hails from Australia though recently became a U.S. citizen. He is an accomplished and experienced seaman and has painstakingly rebuilt his classic Herreshoff Fish Class sailboat SHAD, along with its tender ROBOAT. He is well-read, articulate, thoughtful, always polite and a pleasure to work with. Steve is a long-time resident of Stonington with his wife of many years, Barbara.

Dodson Boatyard has a tradition of gifting a Rolex watch to employees who achieve a 20 year tenure.

Today, Dave Boisvert will receive his. Steve Kingsland has had one for some time now so perhaps it’s time for the most highly sought after Rolex, the Submariner with champagne sapphire and diamond face! We are proud and grateful to have had both of these gentlemen with us for the past many years and hope you will join us in thanking and congratulating them.

It's All About The Service

Beyond this beautiful, protected, scenic harbor. Beyond this scenic, well-kept village. Beyond all else, Dodson Boatyard prides itself on providing high level, efficient, personal, and timely service to its customers. There is no better reflection of that commitment to this critical component of its operation than the recently acquired service vessel M/V ALERT. ALERT is a 30’ military grade custom built craft constructed by Safe Boat International of Bremerton, WA. Dodson Boatyard acquired the boat in 2016 and it quickly proved its worth. If you were here last season it is likely you’ve seen it at its slip at the head of the main dock. Though it appears to be a large HBI, it is actually an aluminum hull surrounded by large fenders, and is equipped with a large hardtop and four dampened seats including seat belts, arm and foot rests and handles, allowing for secure high speed movement. It is fully equipped with all essential safety equipment, has towing capability and is powered by twin 250 HP Honda outboards enabling (very) speedy access to locations from western Long Island Sound, eastern Long Island, and the Massachusetts islands. Indeed, during the 2016 season ALERT logged 286 hours of transit to and from service calls. (Examples of transit times include 45 minutes to Shelter Island or 2 hours to Greenwich, CT, Oyster Bay, NY, or Nantucket. All of these times are significantly less than road travel.) The crew of ALERT always includes experienced technicians and qualified boat handlers. The rapid response time availed by this exceptional asset truly sets Dodson Boatyard’s service capability beyond any other known boatyard in our region.

30' Military Grade SafeBoat

Keep On Truckin'

Several years ago Dodson Boatyard acquired a three shed (ex-moving company) storage facility located in Hopkinton, Rhode Island only 12 miles from the yard in Stonington. (Local zoning restrictions had prohibited Dodson Boatyard from expanding its shed space on-site.) Dodson Boatyard first leased but then purchased this facility while significantly upgrading the buildings to “yacht standards”. A warm shed protects the interior of the yachts from the cold and wet. Since then, two more sheds have been built, all now with concrete floors, excellent lighting, and climate controlled capability. In the “early days” Dodson Boatyard subcontracted out the necessary over-the-road trucking needs however it soon made economic as well as operationally efficient sense to create its own in-house trucking operation. Accordingly, a cab/truck and a 35 ton capacity hydraulic Brownell trailer were acquired and Alan Smith, a veteran Dodson Boatyard mechanic/technician earned his CDL (Commercial Driver’s License) in order to operate this heavy equipment. During the past several years, as the shed space increased, so too has the size, and quality, of the storage yachts we have the privilege to care for. It was a good problem to have! Consequently, a larger Peterbuilt truck has been purchased and in early summer of this year Dodson’s will take possession of a brand new, larger (45 ton), custom-built, triple-axle, air-ride, hydraulic Brownell trailer. This significant upgrade to the Yard’s boat transportation capabilities will not only provide for the movement of larger, heavier vessels but with two complete rigs now at our disposal, we will be far more efficient during our hectic hauling and launching seasons.

25 Ton Brownell Hydraulic Trailer

Efficiencies

We thought it might be of interest to describe some of the ways that Dodson’s has evolved over the years, in particular, regarding our on-going efforts to more efficiently deliver the services of a first class boat yard. Many of us here have been in this business for a long time and well remember the days without poppets (boat stands) and the only alternative to supporting boats was either cumbersome steel cradles and lots of heavy blocking or both. Needless to say, the process was slow and labor intensive. An investment in thousands of various sized adjustable metal poppets, in the last four decades, helped immensely. And then there was the process of hauling, moving and relaunching the boats. When the Snyder family acquired Dodson Boatyard in 1980, railways, greased skids, steel cables and pulling trucks were relied upon to move boats out of the water and into sheds. Easy? No. Efficient? Not! Since then, various sized Travelifts have seen service, including our current 5 ton remote controlled crane. Viva la difference! Another significant improvement in our operational efficiency was the addition of our hydraulic crane used for stepping and un-stepping masts. The crane is located adjacent to the work basin, extends to 120 feet, and has a capacity of 10,000 pounds. It too, like our large Travelift, can be operated remotely. Please note that the remote capabilities of the crane as well as the 85 ton Travelift contributes not only to more efficient operations but more importantly to the safety of our staff and the products being handled. (Note: Dodson Boatyard has achieved the lowest possible Workman’s Compensation experience modification rate allowed by state law, a function of negligible work site accidents.) But wait. There’s more. Dodson Boatyard custom ordered a 35 ton hydraulic self-propelled boat trailer in 1989. It was the first of its’ kind. Since then the yard purchased another custom made 45 ton boat mover.

Efficiencies of course are realized in more subtle ways such as our practice of sanding boat bottoms prior to moving boats indoors for winter storage; or carefully labelling and organizing gear that is removed from boats (e.g. spreaders, poles, sails, personal items, etc.); or carefully reviewing each boat’s condition at lay-up in order to avoid Springtime “surprises”; or using a designated forklift and specially designed pallets for moving necessary blocking used for supporting a boat’s keel; and more… Indeed, elsewhere in this newsletter we describe our high speed service vessel ALERT, our expanded over-the-road trucking fleet, and our in-house sail care operation. Dodson is committed to continue to find ways to improve through significant, annual infrastructure investment and creative thinking, with the goal to provide highly competitive value and cost effective service. It is an on-going effort.

Employee Spotlight

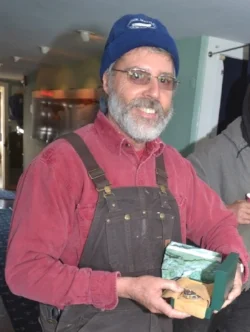

All good organizations are defined by its members and Dodson Boatyard is no exception. We are truly a team however, 17 year veteran Alden Holdridge probably deserves the title “First among equals” more than anyone. What a wonderful surprise it turned out to be as Alden possessed vastly more innate abilities than what might have been inferred on his resume. He brought intellect, mechanical aptitude, problem-solving skills, dedication, a strong work ethic, and exceptional personal skills to every assignment he is given. He has grown to become an essential force in and contributor to the growth of Dodson Boatyard. He is a superb master mechanic, the go-to person for internal computer software/hardware issues, and a service manager extraordinaire, including complete oversight of our winter storage/service operation in Hopkinton, RI. Further, he is frequently the operator and mobile technician on Dodson Boatyard’s “fast attack” service vessel ALERT (see associated article in this newsletter.) As Alden’s career blossomed so too has his personal life. He and his wife Jen share their lives and home in Mystic with their three terrific children. We are exceptionally fortunate to have Alden on our staff.

Alden Holdridge, a seventeen year employee.

Dodson Sail Care

Dodson Boatyard continually searches for ways to be more efficient. One of its more recent efforts has been to establish its own in-house sail and canvas care operation. Thirty year sail industry veteran John Lucey agreed to sign on and set-up this new extension of Dodson’s full-service offerings and initiated it in 2015. With John’s help, Dodson Boatyard purchased the shop inventory from Halsey/Evolution Sails, which had ceased operations, in order to provide the necessary equipment with which to get up and running. It is important to point out that Dodson Sail Care extends beyond the actual necessary maintenance of sails and canvas. Typically the service begins in the fall during the decommissioning process. John and his team are assigned the task of removing a boat’s sail and canvas inventory (sails, dodgers, biminis, sail and brightwork covers, etc.) During this process all items are inspected, digitally photographed, and noted for any immediate or preventative maintenance repairs. A report is then generated, shared, and discussed with the owner. Work is thus scheduled in a timely manner. All repair and cleaning work is completed at a dedicated section in one of Dodson Boatyard Hopkinton, Rhode Island sheds. The last phase of this service occurs when John and his team reinstall the sails and canvas at spring commissioning. After two seasons in operation, we have received enthusiastic feedback from our customers regarding both the quality of work performed as well as the efficiencies (including cost savings) of the operation. Finally, Dodson Sail Care does not build new sails or canvas products. We are pleased to continue to work with each customer’s preferred choice of a sail and canvas loft.

Sail care in Dodson's Hopkinton, Rhode Island facilities.